NEWS CENTER

ZhangsFlock Your Trusted Flock Powder Manufacturer

Introduction In the world of product customization, flock printing stands out as a unique and valuable technique. Whether you’re looking to add a luxurious feel to apparel, enhance automotive interiors, or create a premium unboxing experience, flock printing offers a soft, velvety texture that can elevate the aesthetic appeal of any product. But where can you find the best flocking supplies and reliable flock powder manufacturing? Enter ZhangsFlock—a leading flock factory committed to providing high-quality flocking solutions tailored to meet the needs of industries worldwide. In this blog, we’ll explore the process behind flock powder manufacturing, the essential supplies needed for flock printing, and why ZhangsFlock should be your go-to partner. What is Flock Printing? Flock printing is the process of applying fine, short fibers (flock) to a surface using an adhesive. These fibers are charged electrostatically and applied to materials like fabric, paper, plastics, and more. The result is a plush, soft texture that provides both visual and tactile appeal. At ZhangsFlock, we specialize in offering flocking supplies that deliver superior results, ensuring your products stand out with luxurious textures that improve both their functionality and aesthetics. Our Flock Powder Manufacturing Process At ZhangsFlock, we take pride in the meticulous process of flock powder manufacturing. Here’s a brief look at how we create the premium flock powders that are used for flock printing: Cutting:We use specialized cutting machines to precisely cut fibers to the desired length for the flock printing process. Dyeing Color:Our dyeing process ensures the flock powder matches the exact color requirements of your project. In this step, we also treat the fibers to enhance their conductivity and electrostatic properties, which are vital for successful flocking. Drying:After dyeing, the flock fibers are carefully dried to ensure optimal moisture content, preserving the fibers’ lightweight nature and preventing clumping or uneven flocking. Sieving:Once dried, the fibers are sieved to separate the standard-size flock from longer fibers. This guarantees a uniform distribution of flock fibers, ensuring the highest quality results. Through this precise flock powder manufacturing process, ZhangsFlock guarantees consistency and quality in every batch, making us your trusted partner for all flocking needs. Why Choose ZhangsFlock for Your Flocking Supplies? As a premier flock factory, ZhangsFlock offers a range of advantages that make us the preferred choice for businesses seeking high-quality flocking supplies: High-Quality Flock Powder:Our flock powder is produced with strict quality control standards, ensuring a smooth, even finish every time. Customization Options:We offer custom flock printing solutions, allowing you to create unique designs with precise colors, textures, and fiber compositions. Fast Lead Times:With a monthly production capacity of 150 tons and a lead time of just 10-15 days, we ensure quick turnaround times, so your project stays on track. Expert Support:Our team provides in-depth technical support and consultation, helping you select the right flock powder and guiding you through the flocking process for optimal results. Sustainability:At ZhangsFlock, we prioritize eco-friendly practices by using sustainable raw materials and ensuring minimal waste during the manufacturing process. Applications of Flock Printing and Flock Powder Manufacturing The versatility of flock printing makes it ideal for a wide range of industries. Here are just a few examples of where flocking supplies can elevate your products: Apparel Automotive Home Décor Packaging Custom flock printing is a popular choice in the fashion industry to add logos, designs, and textured patterns to garments. Flocked designs give clothing a rich, luxurious feel that resonates with high-end markets. Flocked interiors, such as dashboards and door panels, are a staple in the automotive industry. The soft, plush texture not only improves the aesthetics but also provides benefits like sound insulation and anti-slip properties. From cushions to wallpaper, flock printing adds a touch of elegance to home décor items, making them feel more refined and inviting. Flock printing is widely used in premium packaging for luxury products. Adding flocked finishes to packaging materials enhances the unboxing experience and gives a high-end, tactile appeal. The ZhangsFlock Advantage Working with ZhangsFlock for your flocking supplies offers several benefits: Experienced Team: With years of expertise in flock powder manufacturing, our team can provide guidance and insights to ensure the success of your project. Quality Assurance: We maintain strict quality standards in all our processes, ensuring that our products meet industry requirements for consistency, durability, and performance. Customer-Centric Approach: We prioritize customer satisfaction, offering flexible solutions to suit your unique needs. Whether you're looking for custom flock printing or large-scale production, we have the capacity to support your business. Conclusion If you're looking for top-tier flocking supplies and expert flock powder manufacturing, ZhangsFlock is the partner you can trust. With our commitment to quality, fast lead times, and customizable flock printing solutions, we ensure that your products achieve the desired finish, whether it's for fashion, automotive, home décor, or packaging applications. Ready to elevate your products with premium flocking? Contact ZhangsFlock today to learn more about our high-quality flocking supplies and custom flock printing services.

Printed Flock Fabric: Electrostatic Flocking & Supplier Insights

Printed flock fabric is an innovative textile that combines a soft, velvety texture with intricate designs. Its production relies on a process called flock printing, which uses tiny fibers (called flock) to create a raised, textured effect on fabrics. In this blog, we will explore the fascinating world of electrostatic flocking, its benefits, how to find reliable suppliers, and more. What is flock printing on fabric? -What is the meaning of printed fabric? -What is flocking fabric used for? -What is the electrostatic method of flock printing? What is electrostatic flocking? -What is the process of electrostatic flocking? -The benefits of electrostatic flocking Recommended different types of flocking service providers How to Find Reliable Electrostatic Flocking Suppliers: Zhangs -Custom flocking service -Reliable flocking machine manufacturers -Provide flocking materials such as flocking fiber and flocking glue Environmental Considerations in Electrostatic Flocking -Eco-friendly practices in electrostatic flocking -How flocking suppliers are reducing environmental impact in textile manufacturing? Market Trends: The Future of Printed Flock Fabric What is Flock Printing on Fabric? What is the Meaning of Printed Fabric? Printed fabric refers to any textile material that has been decorated with designs, patterns, or colors using various techniques. This can include traditional screen printing, digital printing, or even more specialized methods like flock printing. Flock printing involves the application of short fibers onto a fabric's surface, which results in a velvety, raised texture that can be printed in intricate designs. The fibers are applied to the fabric through a process that uses adhesive and electrostatic forces to "flock" the fibers to the material. What is Flocking Fabric Used For? Flocking fabric is used in a variety of applications across different industries. Its luxurious, soft feel and the possibility for vibrant and detailed designs make it ideal for: 1.Fashion: Creating garments with raised patterns for unique textures and appearance. 2.Home Décor: Upholstery, drapery, and rugs with a rich, velvety feel. 3.Automotive Interiors: Dashboard covers, seat upholstery, and more. 4.Packaging: High-end, luxurious packaging solutions for cosmetics, perfumes, and gifts. The versatility and aesthetic appeal of flocked fabric make it a popular choice in both functional and decorative textiles. What is the Electrostatic Method of Flock Printing? The electrostatic method of flock printing is a highly effective technique where fine fibers are applied to a fabric using an electrostatic charge. These fibers are typically made of materials like nylon or rayon and are applied to the fabric's surface that has been pre-coated with an adhesive. In this process, the adhesive-coated fabric is subjected to an electrostatic field that causes the flock fibers to stand upright as they land on the fabric. The fibers are held in place by the adhesive, resulting in a raised, textured design that is both durable and visually appealing. What is Electrostatic Flocking? What is the Process of Electrostatic Flocking? The process of electrostatic flocking involves several key steps: 1.Preparation of the Fabric: The fabric is first pre-treated with a special adhesive or bonding agent. This ensures the flock fibers will adhere to the surface. 2.Application of Electrostatic Field: Once the adhesive is applied, the fabric is exposed to an electrostatic field, which causes the flock fibers to stand upright and attach to the surface. The fibers are typically very short and light, allowing them to form a dense, uniform coating. 3.Curing: After the flocking process, the fabric is cured to set the adhesive, ensuring that the flock fibers stay in place for a long time. 4.Finishing: The final step may involve trimming any excess flock or adding other finishing touches to enhance the texture and appearance. This method provides a high level of precision, allowing manufacturers to create complex patterns and designs on fabric with a soft, luxurious texture that enhances the product’s visual appeal. The Benefits of Electrostatic Flocking There are several advantages to using electrostatic flocking in textile production: 1.Durability: The flocked fibers are securely adhered to the fabric, ensuring they remain in place even after repeated use and washing. 2.Aesthetic Quality: Electrostatic flocking produces a soft, velvety texture that adds depth and visual appeal to the fabric. The raised fibers catch the light differently, creating unique patterns and finishes. 3.Design Precision: This method allows for intricate and detailed designs, which is ideal for high-end fashion and decorative items. 4.Cost-Effectiveness: Electrostatic flocking can be more economical than other methods of texturing fabric, particularly for large-scale production. Recommended Different Types of Flocking Service Providers Depending on your specific needs—whether it’s custom designs, large-scale manufacturing, or specialized applications—different flocking service providers may be more suitable. Below are some examples of types of suppliers you might consider for different uses: Application Recommended Flocking Service Providers Examples Fashion and Apparel Custom flocking services with high-quality designs and finishes. Zhangs Flocking, FlockTech Inc. Home Décor & Upholstery Large-scale flocking services for upholstery and fabric coverings. VelvetyFlock Co., FlockStyle Automotive Specialized flocking for automotive interiors, offering durability. AutoFlock Suppliers, FlockPro Luxury Packaging High-end flocking services for packaging, focusing on texture and design. LuxFlock Solutions, SoftWrap These service providers can help with everything from custom flock designs to large-scale commercial flocking, depending on your project requirements. How to Find Reliable Electrostatic Flocking Suppliers: Zhangs Custom Flocking Service When searching for a reliable electrostatic flocking supplier, one key factor to consider is whether they offer custom flocking services. This is particularly important if you are looking for unique, tailored designs for your fabric. Companies like Zhangs Flocking offer extensive customization options for small runs or large orders, ensuring that you can achieve the exact look and texture you desire. Reliable Flocking Machine Manufacturers A reputable electrostatic flocking supplier should also be able to offer flocking machines or direct you to reliable manufacturers. These machines are crucial for producing consistent and high-quality flocked fabric. Choose suppliers that are known for their advanced equipment and technology to ensure the best results. Provide Flocking Materials such as Flocking Fiber and Flocking Glue Good electrostatic flocking suppliers should provide not only the flocking service itself but also the materials necessary for the process. This includes flocking fibers (in various colors, lengths, and materials) and flocking glue that is suitable for the fabric type you are working with. Make sure your supplier offers high-quality materials that ensure durability and aesthetic appeal. Environmental Considerations in Electrostatic Flocking Eco-Friendly Practices in Electrostatic Flocking As environmental concerns continue to grow, it’s important to consider eco-friendly practices in the electrostatic flocking process. Many suppliers are now adopting greener methods by using non-toxic adhesives and sustainably sourced flock fibers. Additionally, some flocking services have implemented recycling programs for excess fibers, reducing waste during production. How Flocking Suppliers are Reducing Environmental Impact in Textile Manufacturing Leading flocking suppliers are now taking steps to reduce the environmental impact of their manufacturing processes. This includes using water-based adhesives, implementing energy-efficient flocking machines, and reducing the use of harmful chemicals. By choosing eco-conscious suppliers, you can help ensure that your products align with sustainable and responsible textile production practices. Market Trends: The Future of Printed Flock Fabric The future of printed flock fabric looks promising, with increasing demand for both high-end and mass-market applications. Innovations in electrostatic flocking technology are opening up new possibilities for more intricate and sustainable designs. 1.Growing Demand in Fashion and Home Décor As consumers increasingly seek personalized and high-quality products, the demand for printed flock fabric in fashion and home décor is expected to rise. Designers are now experimenting with flocked fabrics to create bold, textured patterns that elevate the tactile experience of textiles. 2.Technological Innovations in Flocking The future of electrostatic flocking will likely involve even more precise techniques, allowing for even finer flock fibers and more intricate patterns. As technology advances, the cost of flocked fabrics will decrease, making it more accessible for a broader range of industries. Conclusion: Making the Right Choice for Your Flocking Needs Choosing the right printed flock fabric and finding reliable electrostatic flocking suppliers is crucial for ensuring your product meets high standards of quality and durability. Whether you are creating custom designs, scaling up production, or focusing on eco-friendly practices, understanding the flocking process and supplier options is key. By selecting a trusted supplier, you can bring your creative visions to life while ensuring sustainability and long-lasting results in your fabric designs. Recommended Reading: 1.Exploring Flock Printing in Textiles 2.How to Print on Fabric:Flocking Printing VS. Digital Fabric Printing 3.Flock Printing: One of the Four Major Printing Methods

How to Use Flocking Powder for Christmas Decoration in 2025?

Christmas decorations are a way to express creativity, bringing festive cheer to your home. One of the best ways to add that magical snowy effect to your holiday décor is by using flocking powder. Whether it’s for your Christmas tree, wreaths, or greeting cards, flocking powder provides a beautiful and textured finish that mimics the soft, fluffy snow of winter. In this blog, we’ll explore how to use flocking powder for Christmas decorations in 2025, including its benefits, applications, and even how to make your own flocking powder. What is flocking powder? -What is flocking powder made of? -Where to buy Flocking Powder? What is flocking powder used for? -How to use flocking powder on cards? -How to make flocking powder for crafts? -How to make DIY flocking powder? Benefits of using flock powder in Christmas decorations How to make flocking powder for Christmas tree -What is Christmas tree flocking made of? -How to use snow flocking powder to decorate a room? -Steps for making DIY flocking powder for Christmas tree Introducing innovative flocking technology: electrostatic flocking -What is the process of electrostatic flocking? -Electrostatic flocking vs ordinary flocking Conclusion FAQs -What is better, flocking spray or powder? -How to get flocking to stay? -What are the disadvantages of flocking? What is Flocking Powder? Flocking powder is a fine, powdery substance used to create a soft, velvety texture on various surfaces. It’s often used in craft projects to give items a "frosted" or "snowy" appearance. The powder consists of tiny fibers that, when applied to a surface, adhere and create a fuzzy, velvet-like coating. What is Flocking Powder Made of? Flocking powder is typically made from synthetic fibers like nylon or rayon, which are cut into tiny pieces. These fibers can be colored to match the desired effect, such as white for snow or green for moss. The fibers are then finely ground to create a powder form, which can be applied with adhesives or through electrostatic methods. Where to Buy Flocking Powder? You can purchase flocking powder from craft stores, online retailers, or specialty stores. Major online platforms such as Amazon, Etsy, or eBay often offer various types and colors of flocking powder. Some craft retailers also sell flocking powder in specific kits designed for Christmas decorations. What is Flocking Powder Used For? Flocking powder is a versatile tool in both seasonal and year-round craft projects. Its primary use is to create textured finishes on different surfaces, offering a tactile, soft, and visually appealing result. How to Use Flocking Powder on Cards? Using flocking powder on greeting cards or other paper crafts adds a soft, raised texture to certain areas, making them stand out. To use flocking powder on cards: 1.Apply glue or adhesive to the areas where you want the flocking powder. 2.Sprinkle the powder generously over the adhesive. 3.Let it sit for a few minutes, then gently tap off the excess powder. 4.Use a soft brush to clean any loose particles from the card. 5.Allow the card to dry completely. How to Make Flocking Powder for Crafts? Making your own flocking powder at home is a simple process. You can make it by cutting synthetic fibers (like nylon or polyester) into tiny pieces and blending them until they are fine. Once you have your powder, you can color it using fabric dyes or food coloring to match your decoration needs. How to Make DIY Flocking Powder? For DIY flocking powder, you’ll need: Synthetic fibers (such as old nylon stockings or fabric scraps) Scissors or a fabric cutter A blender or food processor Steps: 1.Cut the fabric or fibers into small pieces. 2.Place the pieces into a blender or food processor. 3.Blend until the fibers are ground into a fine powder. 4.If desired, color the powder by adding fabric dye or food coloring. Benefits of Using Flocking Powder in Christmas Decorations Using flocking powder for Christmas decorations offers several key advantages: 1.Creates a Snowy Effect: Flocking powder mimics the look of fresh snow, providing a realistic, frosty effect to Christmas trees, wreaths, and garlands. 2.Adds Texture: The velvety texture enhances the tactile experience, making decorations more interesting and engaging. 3.Versatility: It can be used on a variety of surfaces, including plastic, wood, fabric, and paper, making it suitable for various DIY projects. 4.Durability: When applied correctly, flocking powder adheres well and can withstand handling, making it perfect for long-term decorations. 5.Ease of Use: Flocking powder is easy to apply and can be a fun, creative activity for the whole family. How to Make Flocking Powder for Christmas Tree One of the most popular uses for flocking powder is decorating the Christmas tree. Here's how you can make your tree look like it’s covered in fresh, soft snow. What is Christmas Tree Flocking Made Of? Christmas tree flocking typically consists of synthetic fibers that are dyed white to resemble snow. The fibers are fine and lightweight, making them easy to apply to tree branches without weighing them down. Flocking powder can also contain a bonding agent to help it adhere to surfaces. How to Use Snow Flocking Powder to Decorate a Room? In addition to decorating the Christmas tree, snow flocking powder can be used to create a winter wonderland atmosphere in other parts of your home. Here’s how to use it to decorate a room: Apply flocking powder to garlands, wreaths, or fake snow around your windows. Lightly spray with water or use a bonding spray to ensure it sticks. Use a soft brush to apply the flocking powder to different surfaces for a more natural, snowy look. For an extra touch, consider combining it with lights to create a shimmering, snow-covered effect. Steps for Making DIY Flocking Powder for Christmas Tree 1.Prepare the Materials: You’ll need synthetic fibers (such as nylon or polyester), scissors, a blender or food processor, adhesive spray (or DIY snow spray), and a tree stand. 2.Create the Flocking Powder: Follow the steps mentioned earlier to grind the fibers into fine powder and color it if desired. 3.Prepare the Tree: Place your tree in a sturdy stand and secure it in place. If using a live tree, mist it lightly with water to help the powder stick. 4.Apply the Flocking Powder: Lightly spray sections of the tree with adhesive or snow spray. Then, sprinkle the flocking powder generously over the sprayed areas. You can also shake the powder into the branches and gently tap to distribute it evenly. 5.Finishing Touches: Allow the flocking to dry completely before adding ornaments and lights to your tree. Introducing Innovative Flocking Technology: Electrostatic Flocking With advances in technology, electrostatic flocking has revolutionized how flocking powder is applied. This process uses static electricity to apply fibers to a surface in a uniform, highly controlled manner. What is the Process of Electrostatic Flocking? Electrostatic flocking involves applying an electrostatic charge to the fibers, which then causes them to stand upright when applied to a surface with an opposite charge. This method allows for a much more even and dense coating than traditional hand-application methods. The process is typically used in industrial and large-scale applications but has also found its way into more advanced DIY techniques. Electrostatic Flocking vs Ordinary Flocking 1.Precision: Electrostatic flocking is much more precise, allowing fibers to stand perfectly upright and create a uniform texture. 2.Durability: It results in a stronger, longer-lasting bond compared to ordinary flocking, which may lose fibers over time. 3.Efficiency: Electrostatic flocking is faster and more efficient, especially for larger surfaces. Conclusion: Enhance Your Christmas Decorations with Flocking Powder Flocking powder is a fantastic way to add texture, depth, and a touch of winter magic to your Christmas decorations. Whether you're flocking a tree, wreath, or holiday cards, this versatile material will help you create a festive atmosphere. With innovations like electrostatic flocking, it's easier than ever to achieve professional-quality results at home. For the best results, consider using premium flocking powders or kits that provide high-quality snow effects. If you’re looking for top-notch flocking products, check out Zhang’s range of high-quality supplies to make your holiday season even more magical. FAQs What is Better, Flocking Spray or Powder? Both flocking spray and powder have their advantages. Flocking powder is ideal for a more textured, velvety finish, while flocking spray offers a quicker, easier application. The choice depends on your project’s needs and desired finish. How to Get Flocking to Stay? To make flocking powder stay, use a strong adhesive or bonding spray, and ensure the surface is slightly damp or tacky when applying the powder. What Are the Disadvantages of Flocking? While flocking offers great texture, it can be messy to work with. Additionally, it may not be as durable as other decoration methods, as it can flake off over time or with heavy handling. However, proper application and a good bonding agent can help reduce this issue. Recommended Reading: 1.what is flocking powder made of? 2.How to DIY Snow Flocking Powder: A Complete Guide 3.How to flock a christmas tree:Use flocking kit

Flocking Printing vs. Screen Printing: Which is Best for Your Business?

When it comes to customizing products with logos, designs, or artwork, businesses often face a choice between different printing techniques. Flocking printing and screen printing are two of the most popular methods, but each offers distinct benefits and limitations. This article will dive into the differences between flocking printing and screen printing, helping you determine which is best for your business. What is Flocking Printing? -Materials Used in flock print -Benefits of flock printed What is Flock Screen Printing? -Materials Used in flocking for screen printing -Benefits of screen print flocking Flocking Printing vs. Screen Printing: Key Differences Cost Comparison: Flocking Printing vs. Screen Printing -What is the price of flocking printing? -How much do screen printing cost? Common Applications for Flocking Printing and Flock Screen Printing -custom flock printing -screen printer for shirts Pros and Cons of Flocking Printing vs. Screen Printing -What are the advantages and disadvantages of Flocking Printing? -What are the advantages and disadvantages of Screen Printing? Which Printing Method is Right for Your Business? FAQs -Can you screen print on T-shirts? -Is screen printing easy to learn? -How to make flock print? What is Flocking Printing? Flocking printing is a technique that involves applying small fibers (often nylon or rayon) to a surface using adhesive, creating a velvety, textured design. The process is known for its rich, luxurious finish, adding depth and tactile appeal to the printed material. Materials Used in Flock Print Flocking printing is typically used on materials like cotton, polyester, and various fabrics. The adhesive used can be applied to almost any surface that allows the fibers to adhere effectively, including textiles, paper, and cardboard. The flocking fibers can come in a variety of colors and textures, offering a wide range of customization options. Benefits of Flock Printed 1.Textured, Luxurious Feel: Flock printing creates a soft, velvety texture that adds a touch of sophistication to any product. 2.Durability: Flock prints are long-lasting and resistant to wear and tear, especially when used on fabrics that undergo regular washing. 3.Unique Visual Appeal: The raised texture of flock printing offers a distinctive aesthetic compared to traditional flat prints. 4.Premium Branding: Often used for high-end products, flock printing can elevate the perception of your brand. What is Flock Screen Printing? Flock screen printing is a hybrid method that combines traditional screen printing with flocking. In this process, a design is first screen printed onto a surface with an adhesive layer. Then, tiny fibers (the flock) are applied to the adhesive, resulting in a raised texture. This method allows businesses to create textured prints while benefiting from the efficiency of screen printing. Materials Used in Flocking for Screen Printing Flocking for screen printing can be applied to a variety of materials, just like traditional screen printing. Common substrates include cotton, polyester, and other fabrics. The screen-printed adhesive must be carefully applied to ensure that the fibers stick properly without clumping or causing uneven coverage. Benefits of Screen Print Flocking 1.Efficiency: Screen printing is one of the most efficient methods for large runs of custom designs, and adding flocking enables the creation of texture without sacrificing speed. 2.Customization Options: The use of different adhesives and flocking fibers allows for a wide range of textures and colors, giving businesses flexibility in design. 3.Cost-Effective for Large Orders: Like standard screen printing, flock screen printing becomes more cost-effective as order quantities increase. 4.Durable and High-Quality: The combination of screen printing and flocking ensures durability while offering a premium finish. Flocking Printing vs. Screen Printing: Key Differences While both flocking printing and screen printing are highly effective methods, they serve different purposes and offer distinct features. 1.Texture and Finish: Flocking printing offers a raised, velvety texture, making it ideal for luxury or high-end products. Screen printing provides a smooth, flat finish, which is great for designs with multiple colors or large areas of ink. 2.Cost and Efficiency: Screen printing is generally more cost-effective for larger production runs. It’s quicker and more scalable than flock printing, especially when creating simple designs. On the other hand, flocking printing is better suited for smaller batches or high-end, intricate designs. 3.Durability: Both methods produce durable prints, but flocking tends to be more resistant to fading over time due to its thicker texture. 4.Design Complexity: Flocking printing is better for intricate designs with fine details or textures, whereas screen printing is better suited for bold, solid designs with fewer details. Cost Comparison: Flocking Printing vs. Screen Printing Understanding the costs involved with each method is essential when making a decision for your business. What is the price of flocking printing? While flock printing is highly effective for smaller, specialized orders, the process can be more expensive. The additional materials (adhesive and flocking fibers) and setup time make it less cost-effective for bulk orders. The texture also requires more precise handling, which can increase labor costs. how much do screen printing cost Screen printing is often more affordable for bulk orders. The initial setup costs (screen creation and preparation) are higher, but once the setup is done, printing costs per unit are generally lower. This method is ideal for businesses looking to print large quantities of a design. Common Applications for Flocking Printing and Flock Screen Printing Both flock printing and screen printing with flocking have widespread applications across a variety of industries. Custom Flock Printing Custom flock printing is often used in the fashion and apparel industries to create high-end custom t-shirts, hoodies, and other clothing items. The luxurious texture adds a premium feel to garments, making them more appealing to customers looking for exclusive or limited-edition products. Screen Printer for Shirts Screen printing with flocking is commonly used for custom t-shirts, particularly for larger orders. This method allows for vibrant colors and intricate designs, while the addition of flocking offers a unique, tactile finish. This combination works well for promotional items, team uniforms, and fashion brands. Pros and Cons of Flocking Printing vs. Screen Printing What Are the Advantages and Disadvantages of Flocking Printing? Advantages: 1.Premium, tactile texture. 2.Suitable for intricate and detailed designs. 3.Adds sophistication to the product. Disadvantages: 1.More expensive for large orders. 2.Limited to simpler designs for bulk printing. 3.Time-consuming setup and process. What Are the Advantages and Disadvantages of Screen Printing? Advantages: 1.Cost-effective for large runs. 2.Versatile in terms of design complexity and color options. 3.Quick and efficient for bulk production. Disadvantages: 1.Flat finish with no texture. 2.Limited texture options compared to flocking printing. 3.May not be as suitable for small, intricate designs with high detail. Which Printing Method is Right for Your Business? Choosing the right printing method depends on several factors: 1.Order Size: If you're looking for large quantities of customized products, screen printing is likely your best choice due to its cost-effectiveness for bulk orders. 2.Design Complexity: For intricate designs with textures, flocking printing is ideal. However, if your design is simpler and requires vibrant colors, screen printing might be a better fit. 3.Product Type: Consider the type of product you're printing on. Flocking printing is more suited for high-end items, while screen printing is great for promotional products and everyday wear. 4.Budget: For smaller orders or limited edition products, flock printing offers a premium finish but comes with higher costs. For larger, more straightforward runs, screen printing is more budget-friendly. In conclusion, flocking printing and screen printing with flocking are both excellent choices, but they serve different needs. Flocking printing is ideal for smaller, luxury items that require texture and premium quality. On the other hand, screen printing is perfect for mass production of bold, vibrant designs. Both methods have their own pros and cons, and the best choice depends on your business needs and product requirements. If you’re looking for high-quality, luxurious custom products, Zhangs flocking materials and products are a great option. They offer a wide range of flock printing solutions that can elevate your brand and make your designs stand out. FAQs Can You Screen Print on T-Shirts? Yes, screen printing is one of the most popular methods for customizing t-shirts. It allows for vibrant, long-lasting prints that are perfect for large orders. Is Screen Printing Easy to Learn? Screen printing requires some technical knowledge and skill, but it can be learned with proper training. The process involves creating a screen, setting up the design, and then printing each color separately. How to Make Flock Print? To create a flock print, an adhesive is applied to a surface, and then fine fibers (flock) are applied on top. This creates a raised, velvety texture. The process involves precise application of adhesive and flocking fibers to achieve the desired effect.

What is Flock Printing on Fabric?

Flock printing is a unique and eye-catching method of decorating fabric that combines texture with vibrant design. By applying tiny, soft fibers to a fabric surface, flock print fabric creates a velvety, raised effect, giving garments, upholstery, and other fabric products a luxurious, high-end appearance. But what exactly is flock printing on fabric? In this article, we’ll dive deep into the flocking process, the benefits of flock print fabric, and how it compares to other printing methods. -What is a flock fabric? How to apply flocking to fabric? How to care for flock print fabric? -The Benefits of flock printed fabric -Applications of flock print fabric -Flock Printing vs. Other Printing Techniques Flock Printing vs. Screen Printing Flock Printing vs. Heat Transfer Printing Flock Printing vs. Digital Printing -Where to Buy printed flock fabric or flock printed products? Find reliable flocking suppliers Custom Flock Printing Services FAQs Is flock printing durable? What is the flocking process? How to make flock print? What is Flock Fabric? Flock fabric is any textile material that has been treated with small, fiber-like particles, commonly referred to as flock fibers. These fibers are applied to the fabric’s surface, creating a raised, velvety texture that is soft to the touch. The fibers are typically made from synthetic materials such as rayon or nylon, and they are applied through various methods, including electrostatic or adhesive-based techniques. How to Apply Flocking to Fabric? Flocking involves several key steps to achieve that soft, plush texture. Here’s how it’s generally done: 1.Preparing the Fabric: The fabric must be clean and ready to receive the flock fibers. It is often pre-treated with a special adhesive or coating that allows the fibers to stick to the fabric surface. 2.Applying the Adhesive: A thin layer of adhesive is either screen-printed or sprayed onto the fabric in the desired design or pattern. This step is crucial as it ensures the flock fibers will bond to the fabric and form the desired raised texture. 3.Sprinkling the Flock Fibers: Once the adhesive has been applied, the flock fibers are sprinkled onto the surface of the fabric. In some cases, an electrostatic method is used, which causes the fibers to stand upright and align vertically, giving the fabric a plush feel. 4.Curing and Drying: After the fibers are applied, the fabric is heated or cured to ensure the fibers bond securely with the adhesive. Once dry, the fabric is left with a luxurious, velvety texture. How to Care for Flock Print Fabric? Caring for flock print fabric requires a little extra attention to maintain its appearance. Here are some general care guidelines: 1.Gentle Washing: Always wash flocked fabric gently, preferably by hand or in a delicate machine wash cycle. Use a mild detergent and avoid fabric softeners, as these can weaken the flocked fibers. 2.Avoid Harsh Scrubbing: Do not scrub the fabric too hard, as this can cause the fibers to wear off or become flattened. 3.Air Dry: It’s best to air dry flock print fabric rather than putting it in a tumble dryer. Drying at high temperatures can damage the delicate fibers. 4.Storage: Store flocked items in a cool, dry place, and avoid folding them too tightly to prevent damaging the texture. The Benefits of Flock Printed Fabric Flock printing on fabric offers numerous advantages, making it a popular choice for various applications. Here are some of the key benefits: 1. Unique Texture and Look The raised texture of flock printed fabric gives it a distinctive look and feel that stands out compared to regular printed fabrics. The soft, velvety finish is often associated with high-end fashion and luxury home décor. 2. Durability Unlike other fabric printing techniques, flock printing is known for its long-lasting results. The flocked fibers are securely bonded to the fabric, ensuring that the design remains intact even after multiple washes and wear. This makes it ideal for products that require both durability and aesthetic appeal. 3. Versatility in Design Flock printing can create intricate and detailed designs, from bold logos to delicate patterns. Whether you want a matte finish or a sparkly, glittery effect, flock printing can deliver a wide range of textures and finishes, making it versatile for both fashion and home décor. 4. Luxury Feel The tactile nature of flock printed fabric makes it feel more luxurious than other types of printed textiles. The velvet-like texture adds a premium touch, which is why it's commonly used for upscale products. Applications of Flock Print Fabric Flock printed fabric is used in a variety of industries and applications, thanks to its unique texture and visual appeal. 1. Fashion and Apparel One of the most common uses of flock print fabric is in fashion. From custom t-shirts to designer garments, flocking is used to create textured logos, patterns, and designs that give clothing a high-end, sophisticated look. Brands also use flock printing for creating unique, tactile designs that catch the eye. 2. Home Décor In home décor, flock print fabric adds a touch of luxury to items like curtains, cushions, and upholstery. The soft, velvety texture elevates the aesthetics of any room, making it a popular choice for interior designers looking to create opulent atmospheres in homes or commercial spaces. 3. Promotional Products Flock print fabric is also used in the creation of promotional items, such as branded bags, caps, and other accessories. The tactile appeal of flocking adds a premium feel to promotional products, which can help businesses stand out in a crowded market. Flock Printing vs. Other Printing Techniques Flock printing offers unique benefits, but how does it compare to other popular fabric printing techniques? Let’s explore some common alternatives. Flock Printing vs. Screen Printing Screen printing is a widely used method for applying designs to fabric, but it lacks the texture that flock printing provides. While screen printing is ideal for flat, smooth designs, flock printing creates a raised, velvety texture that adds depth to the design. Flock printing is also more durable in the long term, as the fibers are securely bonded to the fabric. Flock Printing vs. Heat Transfer Printing Heat transfer printing involves applying heat and pressure to transfer a design onto fabric, which creates a smooth finish. In contrast, flock printing offers a tactile, 3D texture that heat transfer printing can’t replicate. Flock printing is also more resistant to fading and wear over time compared to heat transfer methods. Flock Printing vs. Digital Printing Digital printing allows for detailed, full-color designs to be printed directly onto fabric. While it offers great versatility in terms of color and complexity, it lacks the textural dimension that flock printing provides. Flock printing is often preferred when the goal is to create a luxurious, tactile effect. Where to Buy Printed Flock Fabric or Flock Printed Products? If you're looking to buy flock print fabric or flock printed products, there are a few things you need to keep in mind to ensure you get high-quality materials. Find Reliable Flocking Suppliers When sourcing flock print fabric, it's essential to work with reputable suppliers who can provide consistent quality. Look for suppliers who specialize in custom flock printing and offer a wide range of fabric types and flocking options. Be sure to check reviews and request samples to ensure the product meets your needs. Custom Flock Printing Services Many businesses offer custom flock printing services, allowing you to design your own unique fabric. Whether you're creating custom t-shirts, home décor items, or promotional products, working with a reliable service provider ensures that your designs come to life exactly as you envision. Conclusion: Why Choose Zhangs Flocking Products? When it comes to high-quality flock printed fabrics, Zhangs offers a wide range of products that deliver both durability and luxurious texture. Whether you're looking to create custom apparel, home décor items, or promotional products, Zhangs' flocking services provide superior results that make your designs stand out. Invest in Zhangs' flock print fabric for your next project and experience the difference in texture and quality. FAQs Is Flock Printing Durable? Yes, flock printing is highly durable, especially when compared to other printing methods. The fibers are securely bonded to the fabric, ensuring that the design remains intact even after repeated washing and wear. What is the Flocking Process? The flocking process involves applying adhesive to the fabric and then sprinkling or electrostatically applying small fibers to create a raised, velvety texture. Once the fibers are applied, the fabric is heated or cured to ensure the fibers bond to the surface. How to Make Flock Print? To create a flock print, you need to apply a thin layer of adhesive onto the fabric, then sprinkle the flock fibers onto the adhesive while it's still wet. After the fibers are applied, the fabric is cured to secure the fibers in place, resulting in a soft, textured print.

Flocked Ring Boxes Tiny Packages with Big Impact

A ring box is far more than a container—it is a stage, a visual promise, and a tactile introduction to one of life’s most memorable moments. The sensory experience of opening a ring box can set the emotional tone before the ring is even revealed. That’s why many premium jewelers now turn to flocked ring boxes, using velvet textures to increase perceived value, elevate the unboxing experience, and reinforce brand identity. In this comprehensive article, we’ll explore why flocked ring boxes matter, how they are produced, creative customization ideas, practical tips, market trends, and examples. Whether you're a jeweler, brand owner, or design enthusiast, this guide will equip you with the understanding needed to use flocked ring boxes to their fullest potential. Why Choose a Flocked Ring Box? Human beings are wired to respond to touch. While visual cues attract the ey, tactile surfaces evoke emotion—softness suggests comfort, luxury, and care. A flocked surface mimics suede or velvet, offering a gentle, plush feel that ordinary rigid packaging cannot match. When someone lifts a lid and feels the soft flock, that moment becomes part of the memory. A ring box lined or wrapped in flock can emotionally elevate the product inside before it's even seen. Perceived Value and Brand Elevation In luxury goods, packaging is part of the value proposition. A plain box might suffice for budget items, but for engagement rings or high-end jewelry, the packaging must reflect the value inside. Flocked ring boxes subtly communicate that care and quality go into every detail. Many consumers expect a certain level of finish with jewelry. A plush interior, a velvet‑touch lid, and rich colors can justify premium pricing. Protection and Practical Benefits Besides aesthetics, flocking offers practical advantages: Soft cushioning: Helps prevent scratches or rubs on the jewelry. Grip and positioning: The fibers help hold rings in place rather than glaring against a slick surface. Non-glare surface: In photography or showroom lighting, flock does not reflect harsh light as much as glossy surfaces. Anatomy of a Flocked Ring Box To understand the production and design choices, let's break down the parts of a flocked ring box. Substrate / Structure Rigid materials: Paperboard, chipboard, wood, or MDF forms the basic box shell. Hinges or closures: Magnetic, ribbon, or metal hinges must accommodate flocking without compromising function. Interior inserts: Rings are often held in place by slots, foam, or metal posts; these are flocked or lined as well. Adhesive / Binder The adhesive is the binding agent between the substrate and the flock fibers. Good adhesives: Have enough tack (“open time”) to allow fiber placement. Cure cleanly without discoloring or stiffening. Adhere to both substrate and fiber material. Adhesives vary by type: water-based, solvent-based, UV-curable, heat-activated, etc. Flock Fibers Material: Common fibers include nylon, rayon, or polyester. Length & thickness (denier): Short fibers (0.5–1 mm) yield a smooth velvet feel; longer ones produce more pile. Special finishes: Metallic-coated fibers, glitter-infused fibers, etc. Color options: Standard and custom dye batches for brand-color matching. Application Method Electrostatic flocking: Uses electric fields to orient fibers upright for uniform coverage. Spray or manual flocking: Fibers are sprayed or puffed onto adhesive, useful for small runs or DIY. Transfer / heat transfer flocking: Pre-flocked sheets or patches are pressed into place, often used for logos. Finishing & Quality Control After flocking, boxes are cured, excess fibers are cleaned off, and quality checks are done to ensure even pile, no bare patches, and proper fiber retention. How a Flocked Ring Box Is Made — Step by Step Here’s a more detailed walk-through of the process: Step 1: Design & Prototyping Decide on dimensions, hinge type, and interior layout. Create mockups with or without flocking to validate proportions. Test colors and flock density through small swatches. Step 2: Substrate Preparation Sand or smooth surfaces. Apply primers or coatings if substrate is slick (like laminated board or plastic). Mask or protect areas where flock is not desired (hinges, gaps). Step 3: Adhesive Application Use a spray, brush, or screen method to apply adhesive evenly. Let adhesive settle to a tacky stage (depending on adhesive type)—not wet, not dry. Step 4: Fiber Application Electrostatic Method: The box is placed in a grounded position while fibers are charged and sprayed toward it. The electric field helps fibers stand upright and embed into the adhesive. Manual / Spray Method: Fibers are hand-sprayed or puffed. Multiple angles and passes help ensure complete coverage, especially into corners and recesses. Step 5: Curing & Setting After fiber application, boxes are left to cure under controlled conditions (temperature, humidity) or exposed to UV/heat if adhesive type allows. The curing process locks fibers into place permanently. Step 6: Cleaning & Inspection Use soft brushes, vacuum, or compressed air to remove loose fibers. Inspect for uniform pile, color consistency, fiber retention, and finish quality. Retouch minor spots if needed. Step 7: Final Assembly Reattach hinges, insert rings, add padding, or liner if they weren’t flocked directly. Perform a final quality check before packaging and delivery. Creative Customization Ideas for Flocked Ring Boxes One major appeal of flocked ring boxes is how customizable they are. Here are some design ideas: randed Logos & Monograms Embossed flocked logos inside the lid. Laser-cut flock patterns showing contrasting colors or underlays. Foil stamping or hot stamping atop flock surfaces. Gradient & Color-Blended Flocking Mix two or more flock colors to create ombré effects or day-to-night transitions across the box surface or interior. Metallic or Glitter Flocking For sparkle and shine, metallic-coated fibers or glitter-infused flock can be integrated—ideal for premium or special-edition boxes. Texture Combinations Pair flocked surfaces with other textures: Smooth satin or silk interior touches Leatherette exteriors with velvet interiors Matte vs. shiny contrast within the box design 4.5 3D & Raised Designs By layering adhesive or using pattern masks, you can raise certain logo elements or motifs to create dimensional flock patterns—not flat textures but sculpted sensations. 4.6 Hidden Details & Secret Messages Use flocking in discreet or hidden areas—maybe a date inside the lid or initials under a flap—giving an intimate layer of personalization. Market Trends and Consumer Behavior Demand for Textural Packaging Consumers increasingly expect multi-sensory brand experiences. Packaging that appeals to touch stands out in a sea of visual-only boxes. Social & Influencer Impact Because flocked textures photograph well—even in social media and influencer unboxing videos—they boost shareability and brand visibility. Personalization & Low MOQs Advances in small-run packaging and flock transfers allow boutique jewelers to affordably produce personalized flocked ring boxes even in small quantities. Sustainable Flocking Eco-conscious brands now demand: Recycled or biodegradable flock fibers Low-VOC or water-based adhesives Sustainable sourcing and minimal waste Producers who can deliver flocked boxes with green credentials win favour with sustainability-aware audiences. Choosing a Supplier — What to Look For When sourcing flocked ring box suppliers, examine: Feature Importance Material compatibility (paper, wood, plastic) Ensures proper adhesion and finish Adhesive quality and method Affects durability and feel Flock density and pile quality Affects plushness and look Customization options Logos, colors, textures MOQ flexibility Important for small brands Eco-certifications For brands with sustainability goals Turnaround & logistics Critical for timely product launches Ask for sample boxes, technical data sheets, and performance tests—like friction resistance and fiber retention. Tips & Pitfalls in Flocked Ring Box Production Avoid Over-Adhesive Too much adhesive causes fiber clumping and bleeding. Use thin layers and retouch selectively. Humidity & Environment Control Best flocking conditions usually require controlled humidity (e.g. 40–60%) and clean air. Too dry or too humid can impact fiber adhesion and flyability. Corner Coverage Edges and corners are points of failure. Use precise application angles, masking, and extra passes to ensure full coverage. Fiber Shedding & Durability Test samples for shedding, abrasion resistance, and durability. Make sure the adhesive truly binds the fibers. Color Consistency Dye lots vary—ensure repeat orders use the same batch or confirm color match with swatches. Post-Flocking Assembly Wait full cure before assembling hinges, adding padding, or handling heavily. Premature handling can flatten fibers or damage edges. Case Studies Luxury Jewelry Brand Launch A high-end brand launched an engagement ring boxed in a deep navy flocked interior with a gold-foil monogram inside the lid. The packaging alone drew praise in product reviews and unboxing video shares. Boutique Ring Designer A small ring designer used a flocking kit for jewelry boxes to produce custom flocked boxes in low volumes. The tactile luxury helped justify premium pricing despite low production scale. Holiday Limited Edition Box For a holiday collection, a jewelry brand released a red and metallic flocked ring box. The metallic fibers added sparkle, making the box itself collectible. Sustainable Flocked Packaging An eco-brand created a ring box with recycled chipboard and biodegradable flock fibers. Marketing emphasized that the packaging was kept as part of the gift, reducing waste. Future Trends and Innovations Smart flock surfaces: Materials that change color or pattern under touch or light. Digital flock printing: Programmatic control of fiber placement to render images or gradients. Biodegradable and compostable flock materials: Maintaining luxury while reducing environmental footprint. Modular ring boxes: Flock interiors that can detach or reposition, combining reuse with flexibility. Multi-sensory packaging: Pairing flock with scents, sound, or vibration for immersive drink experiences. Conclusion Though small in size, flocked ring boxes wield enormous influence over how a jewelry piece is perceived, presented, and remembered. From emotional resonance to brand distinction, these tiny packaging masterpieces offer sensory richness that flat boxes simply cannot match. Whether you’re designing your own with a flocking kit for jewelry boxes, scaling a line with a professional supplier, or experimenting with custom textures and finishes, the power of flock lies in the feeling it evokes. Even a simple ring box becomes a storytelling device—first touch, first impression, and a lasting memory. When you master texture, you master emotional connection.

Which Glues Work Best for Flocking a Box?

Which Glues Work Best for Flocking a Box? Flocking adds luxurious texture and elegance to packaging, jewelry boxes, and gift presentations—but behind every flawless flocked box is a reliable, high-performing adhesive. Choosing the right glue is essential to ensure flock fibers bond well, stand up to use, and deliver a smooth, professional finish. In this article, we’ll break down the best adhesives for box flocking, how they work, where they shine, and what you need to consider depending on your method (electrostatic, manual, or heat transfer). Whether you're a DIY enthusiast or a packaging pro, this guide will help you select the optimal adhesive for flocking a box. Understanding the Role of Glue in Box Flocking Flocking glue, also known as flocking adhesive or flock binder, is the sticky medium that allows short fibers (flock) to adhere to a surface. It's responsible for: Holding the fibers upright until cured (especially in electrostatic flocking) Ensuring even coverage across flat or curved box surfaces Securing fibers long-term through wear, moisture, and handling A poor glue choice leads to patchiness, shedding, discoloration, or failure to cure. The right glue, on the other hand, creates a clean, soft, velvet-like result that endures. Types of Glue for Flocking a Box Water-Based Acrylic Adhesives Best for: DIY jewelry boxes, cardboard boxes, small craft projects Why it works: Eco-friendly and low in VOCs Easy cleanup with water Dries clear or tinted (varieties available) Compatible with many surfaces: cardboard, paperboard, wood, MDF Limitations: Requires longer drying time May struggle with non-porous surfaces (e.g., certain plastics) Can re-soften if exposed to prolonged humidity or moisture Brands to consider: Suede-Tex Undercoat Adhesive Donjer Flocking Glue Jacquard Textile Adhesive (for smaller applications) Solvent-Based Polyurethane or Rubber-Based Adhesives Best for: Professional packaging, high-volume runs, plastic or lacquered boxes Why it works: Strong bond strength, even on smooth or coated surfaces Faster drying time High durability, moisture resistance Limitations: Higher VOC content (requires ventilation) Flammable and more hazardous to store and handle Cannot be cleaned with water Ideal for: Flocking glossy gift boxes Flocking for jewelry boxes made from acrylic or laminated materials Specialty finishes requiring strong adhesion UV-Curable Adhesives Best for: Industrial, automated flock box production lines Why it works: Instant curing under UV light Precise control for high-speed operations No emissions during curing Compatible with heat-sensitive materials Limitations: Requires UV equipment and controlled environment Not suitable for DIY or small-scale projects Used in: Flocked boxes for luxury cosmetics Medical or tech product packaging with flocked interiors Custom flock transfers on pre-flocked surfaces Heat-Activated Adhesives Best for: Pre-cut flock transfers, raised logos, and precision shapes Why it works: Bonds quickly when heat is applied (via heat press) Durable and flexible Clean finish with no drying time Limitations: Requires heat press or laminator Less flexible for large surface areas May damage heat-sensitive box materials Popular in: Creating flock ring box interiors with precision-cut flocking Custom heat transfer flocking kits Branded flock finishes on gift boxes Matching Glue Type to Box Material Box Material Recommended Glue Type Why Cardboard / Paperboard Water-based adhesive Breathable and absorbent surface MDF / Wood Water or solvent-based adhesive Porous surface, durable bonding Plastic / Acrylic Solvent-based adhesive or UV adhesive Non-porous, strong adhesion needed Leatherette / PU Solvent or heat-activated adhesives Slick surface needs stronger glue Coated Gift Boxes UV or solvent-based adhesive Prevents peeling, good for smooth gloss Factors to Consider When Choosing Flocking Glue Drying Time Fast cure glues (UV, solvent) are ideal for high-volume workflows. Slower cure glues (water-based) offer more time for fiber application. Substrate Compatibility Always test on your specific box material. Some adhesives will not bond well to glossy or waxed surfaces without surface treatment. Application Method Electrostatic flocking: Use adhesives with longer open time and tack. Spray or manual flocking: Use glues with thicker consistency to prevent drips. Transfer flocking: Match glue to heat transfer specifications. Final Texture & Finish Some adhesives dry clear for colored fibers to shine; others are tinted to boost fiber tone or help with coverage visibility during application. Recommended Glue Kits for DIY Flock Boxes If you're creating a flocking kit for jewelry box or doing DIY, consider these kits: Donjer Suede-Tex Flocking Kit Water-based adhesive + puffer bottle + fibers Great for small jewelry boxes Multiple color options available Electrostatic Mini Flocking Kit Includes electrostatic gun, fiber, and conductive adhesive Semi-professional finish for hobbyists and small shops Custom Flocking Adhesive Packs Tailored for specific substrates (plastic, wood, metal) Include options for screen flocking or pattern transfersTip: Use a dedicated flocking tray or box to catch excess fibers for reuse and cleanliness. Application & Clean-Up Tips For water-based adhesives: rinse tools with warm water before the glue sets. For solvent-based adhesives: use acetone or isopropyl alcohol for cleanup. Always wear gloves and work in a well-ventilated area—especially with solvent and UV adhesives. Common Mistakes to Avoid Applying glue too thick: This causes bubbling and uneven flocking. Letting glue dry before fiber application: Always apply flock while glue is still tacky. Using the wrong glue for surface: Non-porous surfaces need stronger adhesives. Skipping primer or sanding on glossy boxes: Prepping the surface improves adhesion. Advanced Glue Techniques Dual-Bonding Layers Apply one thin adhesive layer, let it partially dry, then apply a second layer before flocking for added strength. Colored Adhesive Base Use tinted adhesives (red, blue, black) under matching flock fibers to increase color saturation and avoid "bald spots." Adhesive Masking Use masking tape or stencils to apply glue in patterns, creating flocked logos, borders, or designs on boxes. Choosing the Right Glue Makes All the Difference The success of a flocked box depends heavily on glue choice. No matter how beautiful your fibers or precise your application method, if the adhesive fails—your flocking fails. To recap: Use water-based adhesives for paper, wood, and small boxes. Use solvent-based adhesives for plastic, leatherette, or gloss-coated boxes. Use UV or heat adhesives for industrial, fast-curing needs. Always match adhesive to surface, method, and intended use.

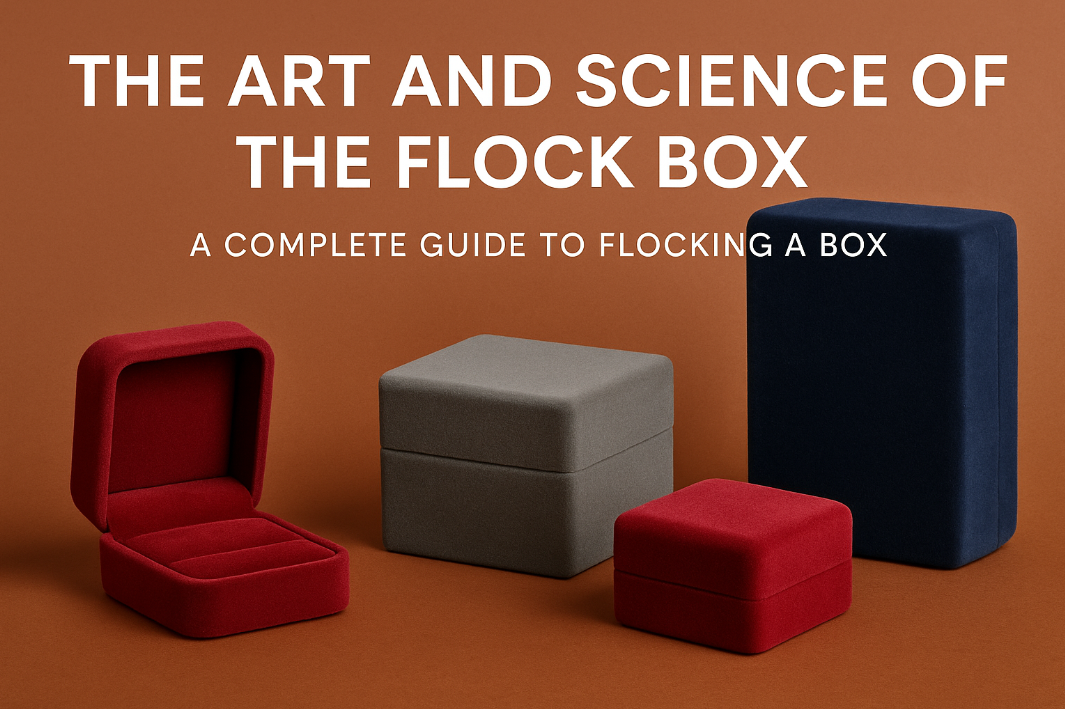

The Art and Science of the Flock Box

The Art and Science of the Flock Box The Allure of Flocked Boxes When you hold a finely made jewelry box, the softness of a velvet‑lined interior often creates as much impression as the item inside. That velvety touch comes from a technique called flocking, which transforms a plain surface into something with depth, luxury, and sensory appeal. A well-executed flock box (or flocked box) elevates perceived value, improves product presentation, and enhances brand experience. Whether you’re a jewelry maker, packaging designer, DIY crafter, or brand owner, understanding how to flock a box or how to flock a jewelry box offers you creative control and a powerful differentiation tool. This article dives deep—starting from fundamentals to advanced techniques—so you can master the process. What Is a Flock Box? Common Expressions & Definitions Flock box / flocked box / box flocking: A box (or container) whose inner or outer surfaces are coated with short fibers to give a velvet-like texture. Flock in a box / flock in the box: Can refer either to DIY kits packaged inside a box or the concept of placing flocked surfaces inside a box. Flocking a box / flocking box: The act or process of applying flock fibers to a box. Flocking for jewelry box: Applying velvet flocking specifically to jewelry boxes. Flock ring box: A small jewelry box often used for rings, lined or coated with flock. Flocking kit for jewelry box: A set of tools, adhesives, and flock fibers packaged for DIY jewelry box flocking. How to make a flock box / how to flock a box : Phrases used by users seeking instructions or tutorials. Historical Context & Why It Matters Flocking has been used for centuries—originally to mimic rich fabrics like velvet by flocking fibers onto surfaces. Over time, technologies like electrostatic flocking, screen flocking, and spray flocking made it more accessible and consistent. In modern packaging, a flocked box signals premium quality, enhances touch experience, and reinforces brand prestige. Whether for luxury jewelry, exclusive gifts, or limited-edition items, flocking transforms the unboxing from a moment into a memory. Core Components of a Flock Box To make a flocked box effectively, you must consider four fundamental elements: Substrate Material The base box can be made from: Rigid paperboard / chipboard MDF or wooden boxes Plastic or acrylic box shells Leatherette or simulated materials You’ll want a substrate that can bond well with adhesives and is stable under the flocking process. Flock Fibers These are the tiny fibers that create the velvet effect. Key considerations: Material: Nylon is durable and colorfast. Rayon is soft and lustrous. Length / Denier: Shorter fibers (0.5–1 mm) produce smooth surfaces; longer fibers (1–3 mm) yield plush textures. Color & Specialty Fibers: You can use metallic-coated fibers, glitter-infused fibers, or color gradients. Flocking powder: Sometimes the fibers are pre-cut into "powder" form to assist in automatic application. Adhesive Flocking Adhesive selection is critical: Water-based adhesives: Low VOC, safer to use, but may take longer to cure. Solvent-based adhesives: Fast curing, strong bond, but riskier to handle. UV-curable adhesives: Instant cure under UV light—excellent for fast production. Heat-activated or pressure-sensitive adhesives: Useful for certain substrates or packaging workflows. Adhesive must be compatible with both the substrate and the fibers, and must remain tacky long enough to accept the fibers before curing. Application Method / Equipment Depending on scale and precision, different methods are used: Electrostatic flocking: Uses high-voltage charge to align and attract fibers. Screen flocking: Patterns of adhesive are screened on, then flock applied. Spray flocking: Manual or automated spray nozzles deliver fibers. Heat transfer flocking: Pre-flocked transfers are pressed onto the box. Manual puffing: Small kits use puffer bottles or manual applicators. Some flocking kits for jewelry boxes bundle small tools for crafters. Step-by-Step: How to Flock a Box Here is a detailed process to guide you through how to make a flock box Step 1: Preparation Clean and prime the box surfaces (dust-free, grease-free). Mask off areas you don’t want flocked (hinges, edges). Pretest a small sample surface if this is your first time. Step 2: Adhesive Application Apply adhesive evenly using spray, brush, or screening. Aim for a thin, uniform coat—too heavy a layer causes smudging; too light leads to weak adhesion. Maintain tackiness until fiber application. Step 3: Fiber Application If using electrostatic flocking: position the high-voltage applicator 8–12 inches away, then feed fibers. For spray or manual methods: use a gentle spray or puff, bringing fibers to the adhesive surface. Use multiple angles to ensure full coverage (corners, cavities). Step 4: Curing Allow the adhesive to set under controlled conditions (dry, dust-free). Time and temperature depend on adhesive type—consult packaging or datasheet. Some adhesives require heat or UV exposure. Step 5: Cleanup & Finishing Gently brush or vacuum off excess, loose fibers. Inspect the flocked box—if there are bare spots, retouch with extra adhesive and fiber. Let it fully cure before use (24 hours recommended in many cases). Tips & Best Practices for High-Quality Flock Boxes Avoid Common Pitfalls Don’t over-wet surfaces or saturate adhesive—causes fiber clumps. Maintain consistent humidity and airflow. Use trays or drop zones to catch overspray. Work in small zones to prevent adhesive drying before flocking. Edge & Corner Flocking Corners and edges are tricky. Some strategies: Use angled nozzles or multi-directional passes. Prefold and mask corners to ensure fibers reach every face. Gentle brushing of edges can help verify coverage. Color Matching & Custom Effects Request flock samples or swatches to confirm exact color. For metallic or glitter flocking box finishes, test small areas first—adhesive strength may vary. For gradient or multicolor effects, layer different flocking passes with masking. Durability & Use Conditions A well-made flock box can last years, but certain conditions challenge it: High humidity or moisture can affect adhesives if not properly sealed. Oils, creams, or harsh chemicals can degrade fibers. Avoid pressing heavily on the flocked surfaces until fully cured. Choosing a Flocking Kit for Jewelry Boxes For DIYers, a flocking kit for jewelry box is ideal. Look for kits that include: Multiple fiber colors Adhesive suited for box materials Applicators (manual puff, small gun, or electrostatic module) Instructions and safety guidelines Kits provide an accessible entry point without needing industrial machinery. Applications & Creative Use Cases Jewelry & Engagement Boxes Flock ring boxes are ubiquitous for engagements. Using flocking for jewelry box, designers employ deep velvet cavities and optional flocked logos on inner flaps. This technique signals premium quality and helps secure the jewelry in place. Luxury Gift Boxes From watches to perfume bottles, brands use flock in a box interiors and exteriors to elevate unboxing experiences. Flocked lids, panels, and inserts create a tactile contrast with smooth exteriors. Collector & Display Cases For high-end collectibles—coins, awards, pens—a flocked interior protects and emphasizes the displayed item. Box flocking provides cushioning, scratch resistance, and a refined visual frame. Decorative & Keepsake Boxes Keepsake boxes, musical boxes, and heirloom containers often use flocked box interiors. Flocking adds a majestic, personal touch to items intended for long-term keeping. Retail & Display Packaging Stores sometimes use flocked display boxes or windowed packaging to showcase premium items. Box flocking in point-of-sale elements adds texture, elevating brand perception. Flocked Gift Presentation for Events Custom flocked boxes for weddings, corporate events, or limited-edition launches help create memorable packaging. Flocking makes the unwrapping moment special. Advanced Techniques & Innovations Special Flocking Box Effects Using metallic flock fibers, box surfaces shimmer with a subtle elegance. For more sparkle, add glitter particles during or after flocking. Because metallic fibers are stiffer, adhesives may need fine-tuning. Multi-Layer / Raised Designs By applying thick adhesive zones, you can create raised, embossed flocked patterns—like logos or motifs—on the interior lid or exterior surfaces. This technique is often used in high-end packaging. Transfer Flocking Some flock box designs employ custom flock transfers or custom flock heat transfers, especially for logos. The transfer is pre-flocked and then heat-pressed onto the box interior. This method is good for detailed or small-volume decorative effects. Custom Flock Printing on Boxes Advanced systems can digitally control adhesive application to render images or patterns directly in flock. This technique—flocking printing services on boxes—lets you produce boxes with intricate designs wholly flocked. Case Studies Luxury Watch Packaging A watch brand introduced a premium edition with a flocked box interior and flocked logo on the lid. The tactile experience elevated customer perception, and the boxes stored and protected the watches elegantly. Jewelry Designer DIY Brand A boutique jeweler used DIY flocking kits to create small batch flock ring boxes in custom brand colors. The result increased perceived value and customer delight. Limited-Edition Perfume Presentation A perfume brand released a gift set inside a flocked interior box with metallic flocked accents. The unboxing video went viral, highlighting the tactile luxury. These examples illustrate how simply adding flocking to a box can transform a product’s presentation and emotional impact. FAQs Question Answer Will the flock dust or fade? If properly cured and bonded, flocked surfaces hold up well. Avoid oils, friction, and high humidity. Can I flock a plastic box? Yes, with suitable adhesive and surface priming (e.g. corona treatment). Can I reuse excess flock fibers? For many systems, yes—unused fibers can be collected and reused. Is electrostatic necessary? For high uniformity and vertical alignment, it’s ideal—but manual or spray methods can work for small projects. How thick should adhesive be? Aim for a thin, even layer. Too much causes bleeding; too little causes poor adhesion. Conclusion A flock box is far more than just fancy packaging—it’s a sensory statement, a brand tool, and a design differentiator. Whether you're using a flocking kit for jewelry boxes, commissioning industrial box flocking, or experimenting with how to flock a box at home, mastering the process gives you control over how your product feels and how your brand is perceived. From engagement ring boxes to gift packaging, decorative keepsakes to retail displays, the applications for flocked boxes are vast and growing. With customization, care, and creativity, your flocked box can become a memorable part of the customer experience.

Where to Buy the Best Flocking Powder?