How Does Electrostatic Flocking Work?

Electrostatic flocking is a fascinating surface treatment technique that blends physics, chemistry, and design. It’s used in industries ranging from automotive and apparel to packaging and electronics to achieve a velvety, functional finish on a wide range of substrates.

In this comprehensive guide, we'll take you through every stage of the electrostatic flocking process, from surface preparation to curing and finishing. We'll also cover its working principles, what is the purpose of flocking, types of fibers and adhesives used and classic flocking equipment.

What is Electrostatic Flocking?

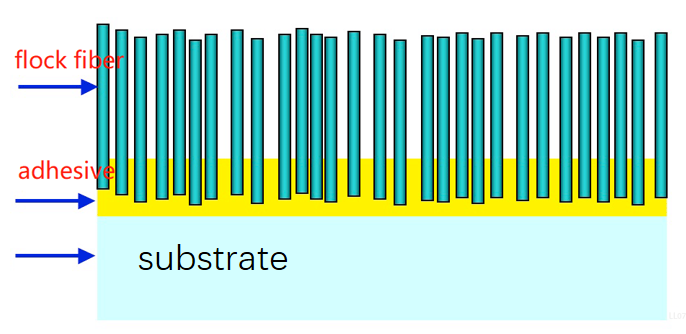

Electrostatic flocking definition is that a manufacturing process in which short fibers (called "flock powder") are applied to a substrate coated with adhesive. An electrostatic field is used to align and embed these fibers vertically, creating a soft-touch, visually appealing, and functional surface. What is the electrostatic method of flock printing? The process utilizes the principles of electrostatics: fibers are charged using high voltage and then attracted to a grounded, adhesive-covered surface. This precise alignment ensures consistent texture, superior fiber density, and minimal waste.

Electrostatic flocking differs from mechanical or gravity flocking, where fibers fall randomly. The electrostatic method offers higher accuracy and better performance—particularly for mass production.

Why Use Electrostatic Flocking?

Electrostatic flocking offers a combination of aesthetic and functional benefits:

-

Visual Appeal: Flocked surfaces mimic velvet or suede, enhancing perceived quality.

-

Soft Texture: Ideal for applications where tactile comfort matters (e.g., car interiors).

-

Improved Grip and Friction: Used on tool handles, packaging inserts, and sports gear.

-

Sound Dampening and Insulation: Flocked surfaces reduce noise and improve insulation.

-

Versatility: Works on various substrates like plastic, metal, fabric, and cardboard.

- High Coverage Efficiency: Electrostatics ensure nearly 100% fiber adhesion with minimal waste.

Aparts from these merits, electrostatic flocking also brings cost-effectiveness to many clothing manufacturers and interesting values to DIY fancier.

The Core Principles Behind Electrostatic Flocking

The electrostatic flock printing method relies on Coulomb’s law: opposite electric charges attract. Here’s how it works:

-

Fibers are electrically charged using a high-voltage generator (typically 40,000–100,000 volts).

-

The substrate is grounded or charged with the opposite polarity.

-

The electric field causes the charged fibers to shoot toward the adhesive-coated surface.

-

The fibers land perpendicular to the surface due to repulsion between like charges.

-

Once embedded in the adhesive, fibers stay locked in place after curing.

The result is a uniform, upright flock pile that provides both a soft texture and a durable finish.

Electrostatic Flocking Process(Step-by-Step Breakdown)

Let’s explore the electrostatic flocking process in full detail, from preparation to finishing.

1. Surface Preparation

The substrate—whether fabric, plastic, metal, foam, or paper—must be thoroughly cleaned and pre-treated. Any dust, oils, or moisture will interfere with adhesion and fiber bonding.

Key actions include:

-

Cleaning: Use solvents, ultrasonic cleaners, or plasma treatment.

-

Drying: Remove all moisture using heat or air drying.

-

Priming: Optional, depending on substrate and adhesive compatibility.

Poor surface preparation leads to weak adhesion, uneven texture, and flock shedding.

2. Electrostatic Flock Adhesive Application

The next step is applying a specialized electrostatic flocking adhesive. This glue acts as a binder between the fibers and the substrate. It must remain tacky during flocking and provide long-term durability after curing.

Common adhesive types:

-

Water-based adhesives: Eco-friendly and suitable for paper, fabric, and wood.

-

Solvent-based adhesives: Fast-drying and strong, ideal for plastics and metals.

-

Hot-melt adhesives: Solid at room temperature, activated by heat.

-

UV-curable adhesives: Cured quickly with UV light for high-speed production lines.

Application methods:

-

Spraying (automatic or manual)

-

Roller coating

-

Brushing

-

Screen printing

-

Dipping (for 3D or irregular shapes)

Key considerations:

-

Even distribution is critical.

-

Avoid bubbles, streaks, or thin spots.

-

Viscosity must be matched to the method of application.

3. Electrostatic Flocking Fiber Application

This is the heart of the process.

Flock fibers (0.3–1.5 mm long) are loaded into an electrostatic gun or chamber. The fibers are charged via a high-voltage grid and propelled toward the adhesive-coated surface.

The target surface is grounded or given an opposite charge, which:

-

Attracts the fibers across the air gap

-

Forces them to align vertically

-

Ensures dense, consistent coverage

Types of electrostatic flocking machines:

-

Manual electrostatic flocking gun: Ideal for small batch or detailed work.

-

Semi-automatic systems: Used in workshops and medium-scale production.

-

Fully automatic systems: Integrated into roll-to-roll or conveyor systems for mass production.

Safety note: Electrostatic systems require strict insulation, grounding, and operator training to prevent electric shock.

4. Curing and Drying

After fiber application, the adhesive must cure to lock the fibers in place.

Curing methods:

-

Oven curing (most common): 80°C to 150°C for 5–30 minutes.

-

Air drying: For low-temperature adhesives; slower and less consistent.

-

UV curing: Instantaneous curing using ultraviolet light.

-

Infrared (IR) drying: Fast and energy-efficient.

Curing stabilizes the flock structure and ensures long-term performance under wear, washing, or environmental exposure.

5. Cleaning and Finishing

After curing, excess or loose fibers must be removed. This step ensures a clean, professional appearance and prevents contamination of other parts.

Finishing techniques:

-

Vacuuming

-

Compressed air blow-off

-

Brushing (manual or rotary brushes)

-

Electrostatic neutralizing (for complex geometries)

The final product is inspected for fiber uniformity, texture, and adhesion strength.

Types of Flock Fibers

Flock fibers are short, thin filaments cut from longer synthetic or natural fibers. Their properties determine the appearance and function of the flocked surface.

| Fiber Type | Characteristics | Common Uses |

|---|---|---|

| Nylon | Durable, UV-resistant, soft | Automotive, apparel, tools |

| Rayon | Shiny, soft, economical | Greeting cards, packaging |

| Polyester | Heat resistant, durable | Outdoor goods |

| Acrylic | Cost-effective, good dyeability | Toys, displays |

| Cotton | Natural feel, breathable | Textiles, crafts |

Important variables:

-

Length: 0.3 mm to 1.5 mm (affects pile height)

-

Denier: Thickness of fiber (affects texture and stiffness)

-

Color: Custom-dyed for branding or design purposes

Substrate Compatibility

Electrostatic Flock Adhesive is used on a wide range of materials. The choice of adhesive and curing method must match the substrate.

| Substrate | Typical Uses | Challenges |

|---|---|---|

| Plastic (ABS, PVC) | Automotive parts, gadgets | Surface treatment needed |

| Metal | Trays, cases, tools | Requires primer |

| Fabric | Logos, fashion, shoes | Flexible adhesives required |

| Paper/Cardboard | Packaging, labels | Sensitive to moisture |

| Foam | Inserts, cushioning | Porous surface affects glue load |

| Glass | Decorative panels | Requires UV or heat-activated adhesives |

Key Applications by Industry

Automotive |

|

Apparel and Footwear |

|

Home Décor |

|

Packaging |

|

Electronics |

|

Printing and Stationery |

|

Challenges and Limitations

While electrostatic flocking machine is highly effective, it has some limitations:

-

Initial equipment investment: High-voltage generators, curing ovens, and clean areas may be costly.

-

Environmental control: Humidity and dust can interfere with fiber adhesion.

-

Adhesive shelf life: Some formulations must be used quickly.

-

Complex geometries: Deep cavities or uneven surfaces require specialized nozzles or multi-axis applicators.

Safety and Compliance

Operators must take proper precautions due to high voltages, solvent vapors, and fine particulates:

-

Use personal protective equipment (PPE)

-

Ensure proper grounding

-

Ventilation systems to control VOCs

-

Comply with regulations like REACH, RoHS, or local emissions laws

Future Trends in Electrostatic Flocking

The flocking industry is evolving to meet modern production and sustainability demands.

Smart Automation |

|

Eco-Friendly Solutions |

|

Hybrid Technologies |

|

Conclusion

Electrostatic flocking is a powerful technique that transforms ordinary surfaces into high-performance, visually engaging, and functional components. Whether you're adding luxury to a car interior or improving product grip, the flocking process offers unmatched versatility and quality. By understanding each step of the process—from adhesive selection to fiber application—you can make informed decisions that boost product appeal and performance. If you're a manufacturer, designer, or engineer exploring surface finishing options, electrostatic flocking is a proven, scalable, and innovative solution worth investing in.