Printed flock fabric is an innovative textile that combines a soft, velvety texture with intricate designs. Its production relies on a process called flock printing, which uses tiny fibers (called flock) to create a raised, textured effect on fabrics. In this blog, we will explore the fascinating world of electrostatic flocking, its benefits, how to find reliable suppliers, and more.

What is flock printing on fabric?

-What is the meaning of printed fabric?

-What is flocking fabric used for?

-What is the electrostatic method of flock printing?

What is electrostatic flocking?

-What is the process of electrostatic flocking?

-The benefits of electrostatic flocking

Recommended different types of flocking service providers

How to Find Reliable Electrostatic Flocking Suppliers: Zhangs

-Custom flocking service

-Reliable flocking machine manufacturers

-Provide flocking materials such as flocking fiber and flocking glue

Environmental Considerations in Electrostatic Flocking

-Eco-friendly practices in electrostatic flocking

-How flocking suppliers are reducing environmental impact in textile manufacturing?

Market Trends: The Future of Printed Flock Fabric

What is Flock Printing on Fabric?

What is the Meaning of Printed Fabric?

Printed fabric refers to any textile material that has been decorated with designs, patterns, or colors using various techniques. This can include traditional screen printing, digital printing, or even more specialized methods like flock printing.

Flock printing involves the application of short fibers onto a fabric's surface, which results in a velvety, raised texture that can be printed in intricate designs. The fibers are applied to the fabric through a process that uses adhesive and electrostatic forces to "flock" the fibers to the material.

What is Flocking Fabric Used For?

Flocking fabric is used in a variety of applications across different industries. Its luxurious, soft feel and the possibility for vibrant and detailed designs make it ideal for:

1.Fashion: Creating garments with raised patterns for unique textures and appearance.

2.Home Décor: Upholstery, drapery, and rugs with a rich, velvety feel.

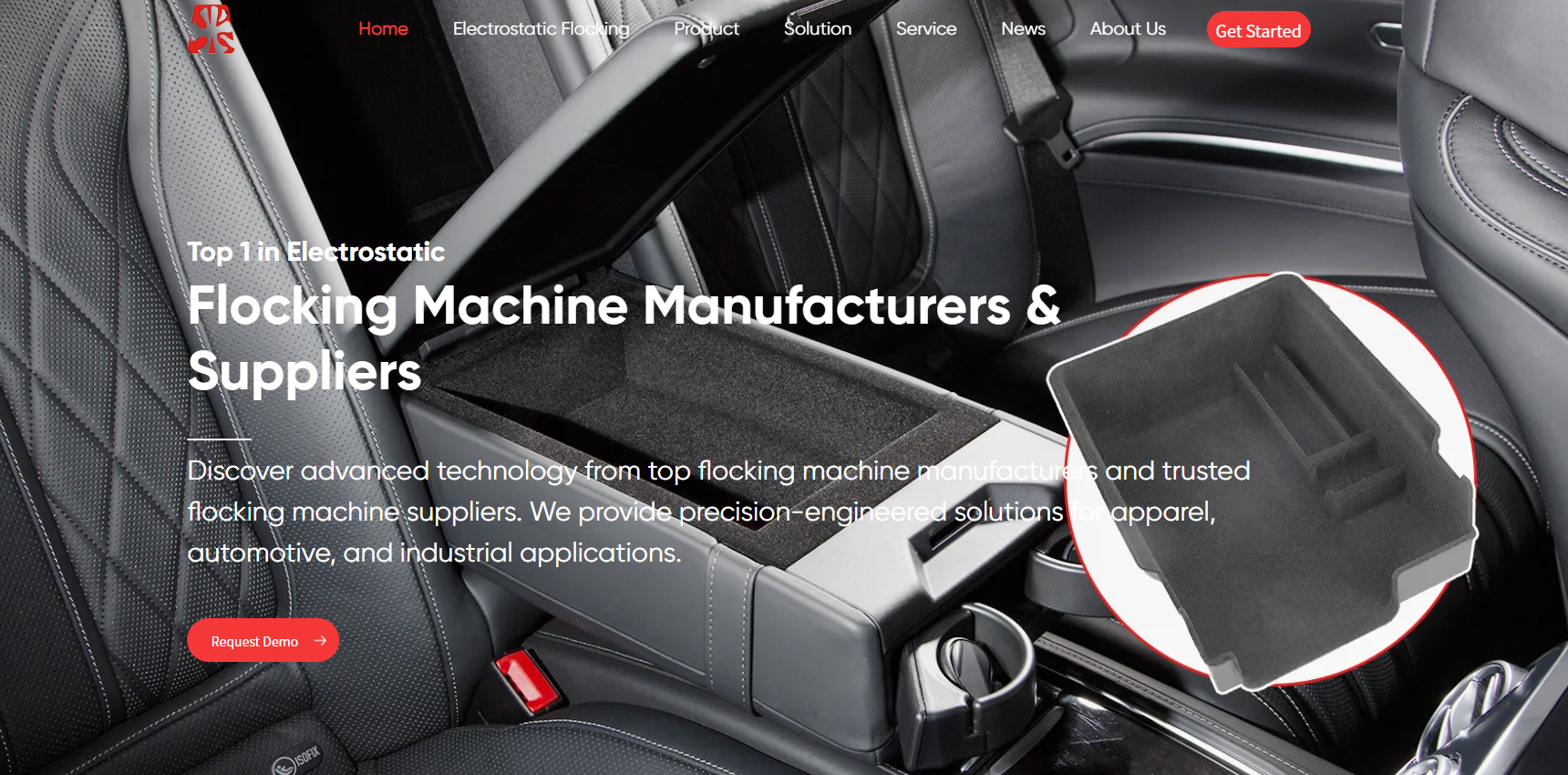

3.Automotive Interiors: Dashboard covers, seat upholstery, and more.

4.Packaging: High-end, luxurious packaging solutions for cosmetics, perfumes, and gifts.

The versatility and aesthetic appeal of flocked fabric make it a popular choice in both functional and decorative textiles.

What is the Electrostatic Method of Flock Printing?

The electrostatic method of flock printing is a highly effective technique where fine fibers are applied to a fabric using an electrostatic charge. These fibers are typically made of materials like nylon or rayon and are applied to the fabric's surface that has been pre-coated with an adhesive.

In this process, the adhesive-coated fabric is subjected to an electrostatic field that causes the flock fibers to stand upright as they land on the fabric. The fibers are held in place by the adhesive, resulting in a raised, textured design that is both durable and visually appealing.

What is Electrostatic Flocking?

What is the Process of Electrostatic Flocking?

The process of electrostatic flocking involves several key steps:

1.Preparation of the Fabric: The fabric is first pre-treated with a special adhesive or bonding agent. This ensures the flock fibers will adhere to the surface.

2.Application of Electrostatic Field: Once the adhesive is applied, the fabric is exposed to an electrostatic field, which causes the flock fibers to stand upright and attach to the surface. The fibers are typically very short and light, allowing them to form a dense, uniform coating.

3.Curing: After the flocking process, the fabric is cured to set the adhesive, ensuring that the flock fibers stay in place for a long time.

4.Finishing: The final step may involve trimming any excess flock or adding other finishing touches to enhance the texture and appearance.

This method provides a high level of precision, allowing manufacturers to create complex patterns and designs on fabric with a soft, luxurious texture that enhances the product’s visual appeal.

The Benefits of Electrostatic Flocking

There are several advantages to using electrostatic flocking in textile production:

1.Durability: The flocked fibers are securely adhered to the fabric, ensuring they remain in place even after repeated use and washing.

2.Aesthetic Quality: Electrostatic flocking produces a soft, velvety texture that adds depth and visual appeal to the fabric. The raised fibers catch the light differently, creating unique patterns and finishes.

3.Design Precision: This method allows for intricate and detailed designs, which is ideal for high-end fashion and decorative items.

4.Cost-Effectiveness: Electrostatic flocking can be more economical than other methods of texturing fabric, particularly for large-scale production.

Recommended Different Types of Flocking Service Providers

Depending on your specific needs—whether it’s custom designs, large-scale manufacturing, or specialized applications—different flocking service providers may be more suitable. Below are some examples of types of suppliers you might consider for different uses:

|

Application |

Recommended Flocking Service Providers |

Examples |

|

Fashion and Apparel |

Custom flocking services with high-quality designs and finishes. |

Zhangs Flocking, FlockTech Inc. |

|

Home Décor & Upholstery |

Large-scale flocking services for upholstery and fabric coverings. |

VelvetyFlock Co., FlockStyle |

|

Automotive |

Specialized flocking for automotive interiors, offering durability. |

AutoFlock Suppliers, FlockPro |

|

Luxury Packaging |

High-end flocking services for packaging, focusing on texture and design. |

LuxFlock Solutions, SoftWrap |

These service providers can help with everything from custom flock designs to large-scale commercial flocking, depending on your project requirements.

How to Find Reliable Electrostatic Flocking Suppliers: Zhangs

Custom Flocking Service

When searching for a reliable electrostatic flocking supplier, one key factor to consider is whether they offer custom flocking services. This is particularly important if you are looking for unique, tailored designs for your fabric. Companies like Zhangs Flocking offer extensive customization options for small runs or large orders, ensuring that you can achieve the exact look and texture you desire.

Reliable Flocking Machine Manufacturers

A reputable electrostatic flocking supplier should also be able to offer flocking machines or direct you to reliable manufacturers. These machines are crucial for producing consistent and high-quality flocked fabric. Choose suppliers that are known for their advanced equipment and technology to ensure the best results.

Provide Flocking Materials such as Flocking Fiber and Flocking Glue

Good electrostatic flocking suppliers should provide not only the flocking service itself but also the materials necessary for the process. This includes flocking fibers (in various colors, lengths, and materials) and flocking glue that is suitable for the fabric type you are working with. Make sure your supplier offers high-quality materials that ensure durability and aesthetic appeal.

Environmental Considerations in Electrostatic Flocking

Eco-Friendly Practices in Electrostatic Flocking

As environmental concerns continue to grow, it’s important to consider eco-friendly practices in the electrostatic flocking process. Many suppliers are now adopting greener methods by using non-toxic adhesives and sustainably sourced flock fibers. Additionally, some flocking services have implemented recycling programs for excess fibers, reducing waste during production.

How Flocking Suppliers are Reducing Environmental Impact in Textile Manufacturing

Leading flocking suppliers are now taking steps to reduce the environmental impact of their manufacturing processes. This includes using water-based adhesives, implementing energy-efficient flocking machines, and reducing the use of harmful chemicals. By choosing eco-conscious suppliers, you can help ensure that your products align with sustainable and responsible textile production practices.

Market Trends: The Future of Printed Flock Fabric

The future of printed flock fabric looks promising, with increasing demand for both high-end and mass-market applications. Innovations in electrostatic flocking technology are opening up new possibilities for more intricate and sustainable designs.

1.Growing Demand in Fashion and Home Décor

As consumers increasingly seek personalized and high-quality products, the demand for printed flock fabric in fashion and home décor is expected to rise. Designers are now experimenting with flocked fabrics to create bold, textured patterns that elevate the tactile experience of textiles.

2.Technological Innovations in Flocking

The future of electrostatic flocking will likely involve even more precise techniques, allowing for even finer flock fibers and more intricate patterns. As technology advances, the cost of flocked fabrics will decrease, making it more accessible for a broader range of industries.

Conclusion: Making the Right Choice for Your Flocking Needs

Choosing the right printed flock fabric and finding reliable electrostatic flocking suppliers is crucial for ensuring your product meets high standards of quality and durability. Whether you are creating custom designs, scaling up production, or focusing on eco-friendly practices, understanding the flocking process and supplier options is key. By selecting a trusted supplier, you can bring your creative visions to life while ensuring sustainability and long-lasting results in your fabric designs.

Recommended Reading:

1.Exploring Flock Printing in Textiles

2.How to Print on Fabric:Flocking Printing VS. Digital Fabric Printing