Electrostatic flocking is a process that uses electrostatic principles to evenly attach short fibers (such as nylon, polyester, etc.) to the surface of a substrate. This process is widely applied in industries such as textiles, packaging, and advertising, and plays an important role in the manufacturing of high-end products. This article will detail the working principle of electrostatic flocking, the equipment used, the process flow, electrostatic flock printing and printing methods, as well as its advantages and applications. Lastly, we will explore how Zhangs Flocking has maintained its leadership in the industry.

How Does Electrostatic Flocking Work?

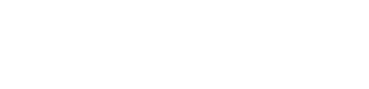

Electrostatic flocking uses electrostatic forces to attach short fibers (also known as "flocking" fibers) evenly to the surface of a substrate coated with adhesive. The substrates can be paper, fabric, plastic, etc. During this process, the charge applied to the fibers causes them to align vertically on the substrate surface under the influence of an electric field, forming a velvety effect. This technique is commonly used for decoration and to enhance the tactile and visual effects of products.

The Principle of Electrostatic Flocking

The basic principle of electrostatic flocking is to use an electric field to charge short fibers with the same charge. These fibers then form an even charge distribution in the electric field, and when they approach the substrate, they are attracted to the surface and align vertically. This results in a uniform flocking effect on the surface.

Flocking Charge

The charge in electrostatic flocking is typically provided by a high-voltage power supply. The voltage applied directly affects the flocking effect. Proper voltage ensures that the fibers adhere evenly to the substrate, while too high or too low voltage can lead to poor flocking results. Proper charge control is key to ensuring high-quality flocking.

What is an Electrostatic Flocking Machine?

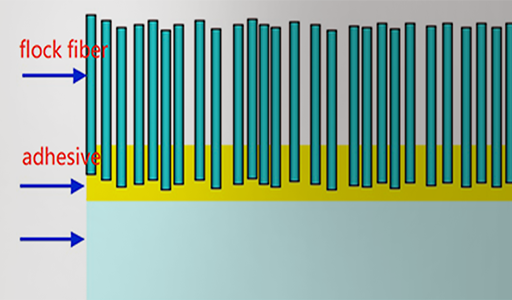

An electrostatic flocking machine is a device specially designed to carry out the electrostatic flocking process. It typically consists of a power supply, spray gun, and a vacuum system. The flocking machine applies high voltage to charge the short fibers, and then the charged fibers are evenly sprayed onto the adhesive-coated substrate using the spray gun. Once the fibers are attached, the substrate is sent into a drying system to ensure the fibers are securely adhered to the surface.

In addition to the machine itself, an Electrostatic Flocking Kit typically includes the necessary accessories to carry out the flocking process. This kit may contain different types of flocking fibers, adhesives, power sources, and applicators, depending on the specific requirements of the project. These kits are especially useful for small-scale or DIY projects, providing a simplified way to achieve the professional-level flocking effect without the need for large, industrial machines. Whether for crafting, upholstery, or product design, electrostatic flocking machines and kits offer an efficient and versatile solution for achieving high-quality, velvet-like finishes on a variety of materials.

What is the Electrostatic Flocking Process?

The electrostatic flocking process consists of several key steps:

Substrate Preparation:

First, the substrate surface must be cleaned to remove dust and impurities, ensuring a smooth surface for the flocking process.

Coating Adhesive:

An even layer of adhesive (usually water-based or solvent-based) is applied to the substrate surface. The choice of adhesive affects the bonding strength of the fibers.

Flocking:

High voltage is applied through the electrostatic flocking machine, causing the charged fibers to attach evenly to the substrate.

Curing:

After flocking, the substrate is cured at an appropriate temperature to ensure strong adhesion between the fibers and the substrate.

Each step requires careful control to achieve the desired flocking effect. Therefore, selecting the right equipment and following the correct procedures are crucial for optimal results.

What is Electrostatic Flocking Printing?

Electrostatic flock printing is a novel technique that combines electrostatic flocking with printing technology. It involves printing part of the design onto the substrate and then using electrostatic flocking to attach fibers to the printed area, creating a raised, embossed effect. This technique is often used in high-end packaging, textiles, and advertising posters, providing unique visual and tactile effects.

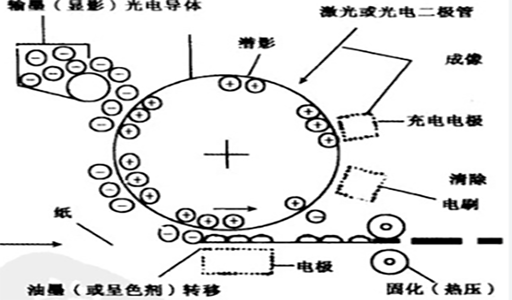

What is Electrostatic Printing?

Electrostatic printing is a method of transferring pigments or inks onto the substrate surface using electrostatic forces. Unlike traditional printing methods, electrostatic printing uses an electric field to attract charged ink particles onto a substrate that has a pattern. This method is characterized by high precision and efficiency, making it ideal for mass production. Electrostatic printing is widely used in packaging, labels, and advertising industries.

Advantages of Using Electrostatic Flocking

Electrostatic flocking offers several significant advantages over traditional flocking techniques:

Efficiency:

The electrostatic flocking process is fast and can complete flocking tasks in large volumes, greatly improving production efficiency.

Uniformity:

The electrostatic field precisely controls the distribution of fibers, ensuring a more even flocking effect, avoiding the unevenness often seen in manual flocking.

Versatility:

Electrostatic flocking can be applied to various materials, including paper, plastic, and fabric, expanding its range of applications.

Environmental Friendliness:

Compared to traditional dyeing or ink processes, electrostatic flocking uses more eco-friendly materials that do not pollute the environment.

Aesthetics and Tactile Quality:

The flocked surface provides a soft texture and enhances the visual appeal, making the product feel more luxurious and high-end.

Broad Applications of Electrostatic Flocking

Electrostatic flocking is widely used across multiple industries, including the following key fields:

Textile Industry:

Electrostatic flocking is commonly used in the manufacturing of plush toys and high-end fabrics, adding unique tactile and visual effects.

Packaging Industry:

High-end packaging boxes, paper bags, and other products often employ electrostatic flocking to enhance their appearance and texture.

Advertising Industry:

Used in the creation of posters and advertising backdrops, electrostatic flocking adds visual appeal to promotional materials.

Automotive Interior:

Electrostatic flocking is used in car seats, dashboards, and other interior components to enhance the luxurious feel and tactile quality.

Toys and Gifts:

Electrostatic flocking is applied to gift packaging and toy surface decorations to increase the perceived value of the products.

As an innovative surface decoration technique, electrostatic flocking has gained widespread application due to its efficiency, environmental friendliness, and aesthetic appeal. With continuous technological advancements, electrostatic flocking not only enhances the appearance, feel, and texture of products but also creates new market demands. Zhangs Flocking, with its advanced equipment and technology, continuously drives innovation in the electrostatic flocking process and offers high-quality flocking services to clients, making it an ideal partner for enhancing product competitiveness.

By adopting electrostatic flocking technology, you can elevate the prestige of your products and inject innovative elements into your brand, ensuring your products stand out in the market.